Mohala o Phahameng ka ho Fetisisa le Li-Cable Extruders

Batho ba ka sehloohong

1, e amohetse motsoako o motle haholo ha kalafo ea naetrojene bakeng sa screw le barrel, bophelo bo tsitsitseng le bo bolelele ba ts'ebeletso.

2, sistimi ea ho futhumatsa le ho pholisa e entsoe ka mokhoa o ikhethileng ha mocheso o ka beoa maemong a 0-380 ℃ ka taolo e nepahetseng haholo.

3, ts'ebetso ea botsoalle ka PLC + touch screen

4, L/D karo-karolelano ea 36:1 bakeng sa lisebelisoa tse khethehileng tsa cable (ho phuphutsa 'mele joalo-joalo.)

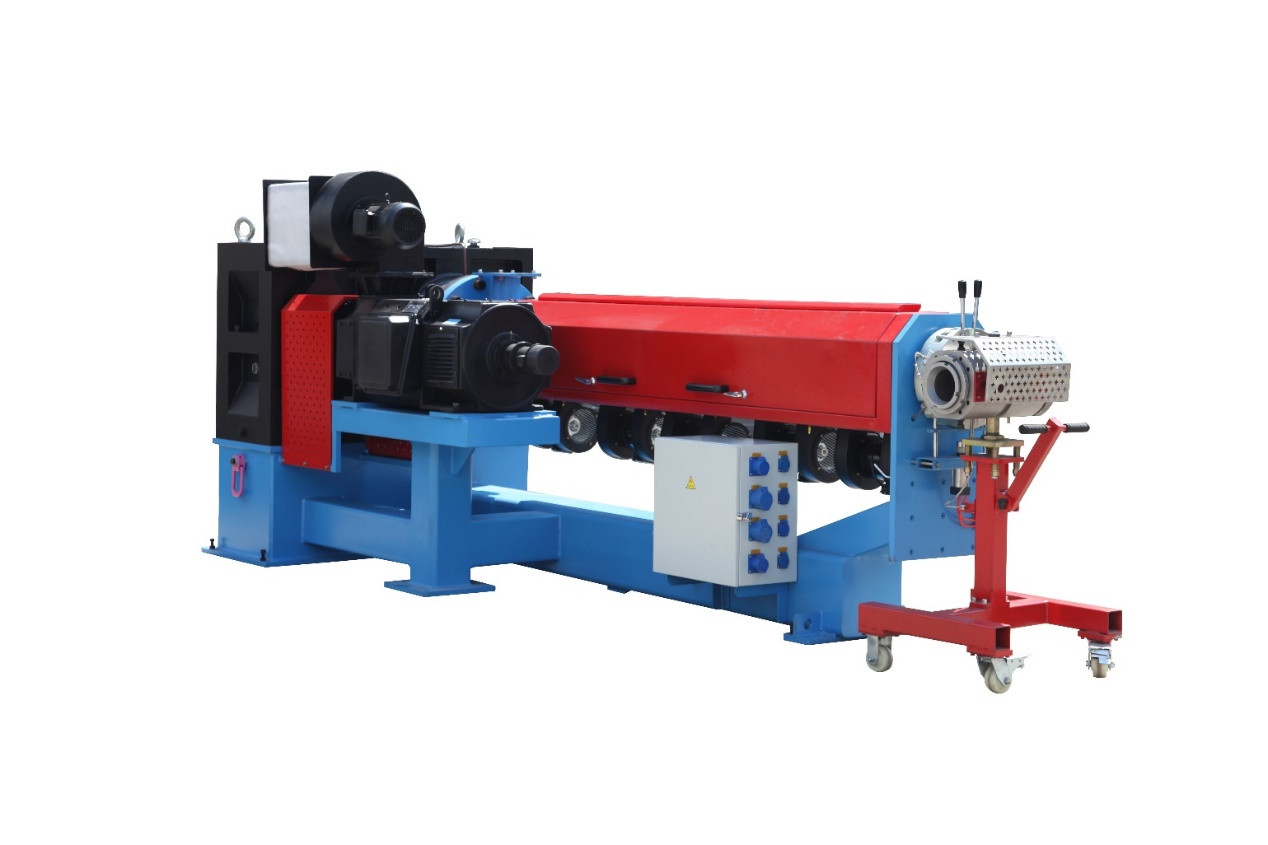

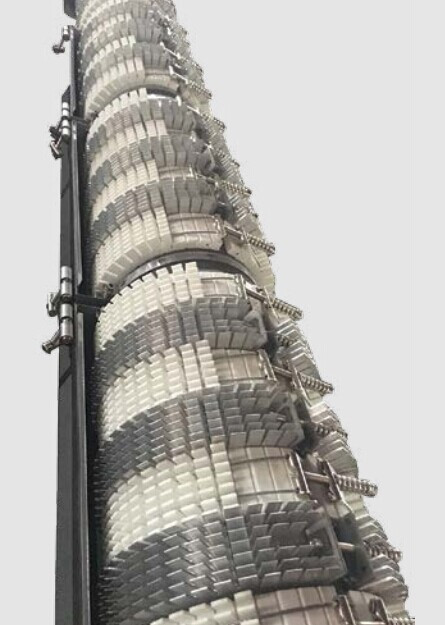

1.Mochine o phahameng oa extrusion o sebetsang hantle

Kopo: Haholo-holo e sebelisoa bakeng sa ho kenya letsoho kapa sheath extrusion ea lithapo le likhoele

| Mohlala | Screw parameter | Bokhoni ba ho eketsa (kg/h) | Matla a maholo a motlakase(kw) | Khoele ea ho tsoa.(mm) | ||||

| Dia.(mm) | Karolelano ea L/D | Lebelo (rpm) | PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

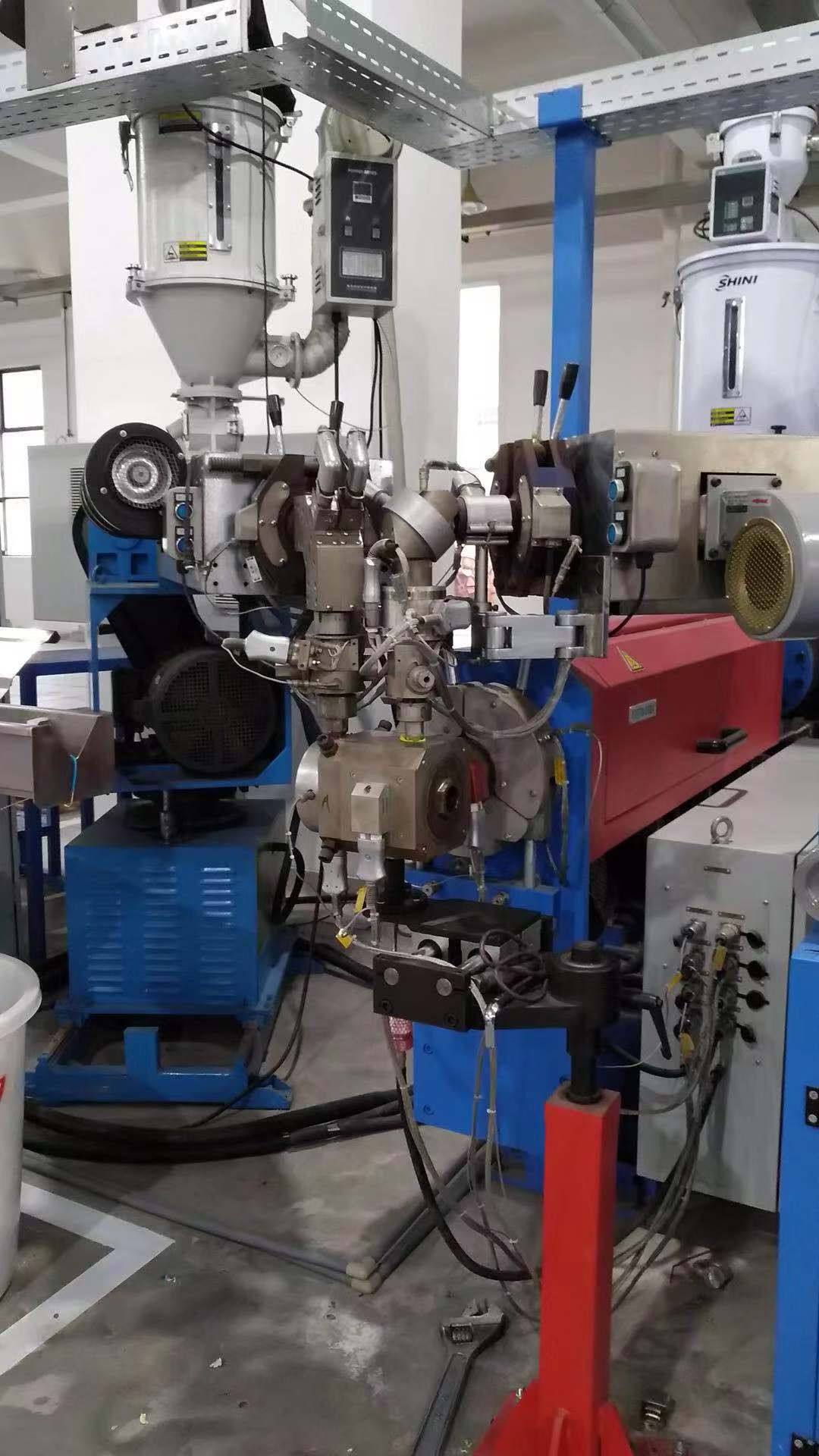

2.Double layer co-extrusion line

Kopo: Co-extrusion line e loketse bakeng sa halogen e tlaase ea mosi, XLPE extrusion, haholo-holo e sebelisetsoang tlhahiso ea lithapo tsa seteishene sa matla a nyutlelie, joalo-joalo.

| Mohlala | Screw parameter | Bokhoni ba ho eketsa (kg/h) | terata e kenang.(mm) | Outlet terata dia.(mm) | Lebelo la mohala (m/mots) | |

| Dia.(mm) | Karolelano ea L/D | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

3.Triple-extrusion line

Kopo: Triple-extrusion line e loketse bakeng sa halogen e tlaase ea mosi, XLPE extrusion, haholo-holo e sebelisetsoang tlhahiso ea lithapo tsa seteishene sa matla a nyutlelie, joalo-joalo.

| Mohlala | Screw parameter | Bokhoni ba ho eketsa (kg/h) | terata e kenang.(mm) | Lebelo la mohala (m/mots) | |

| Dia.(mm) | Karolelano ea L/D | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |