Lihlahisoa

-

Sistimi ea Up Casting ea Cu-OF Rod

Sistimi ea Up Casting e sebelisoa haholo ho hlahisa lere la koporo la boleng bo holimo la oksijene bakeng sa liindasteri tsa terata le lithapo. Ka moralo o ikhethileng, e khona ho etsa li-alloys tsa koporo bakeng sa lits'ebetso tse fapaneng kapa li-profiles tse kang li-tubes le bar ea libese.

Sistimi e na le litlhaku tsa sehlahisoa sa boleng bo holimo, matsete a tlase, ts'ebetso e bonolo, litšenyehelo tse tlase tsa ho sebetsa, e feto-fetoha le maemo ho fetola boholo ba tlhahiso mme ha ho na tšilafalo ea tikoloho. -

Aluminium Continuous Casting And Rolling Line-Aluminium Rod CCR Line

Aluminium e tsoelang pele ea ho lahla le ho roala e sebetsa ho hlahisa aluminium e hloekileng, letoto la 3000, letoto la 6000 le letoto la lithupa tsa aluminium tse 8000 ka bophara ba 9.5mm, 12mm le 15mm.

Sistimi e entsoe mme e fanoa ho latela thepa ea ho sebetsa le matla a amanang le ona.

Setsi sena se entsoe ka sete e le 'ngoe ea mochini o lahlelang mabili a mane, mochini oa koloi, mochini o kutang moriri, mochini o otlolohang le mochini o futhumatsang o nang le maqhubu a mangata, leloala, mochini o roalang leloala, mochini o pholisang ka melamu, coiler le taolo ea motlakase. tsamaiso. -

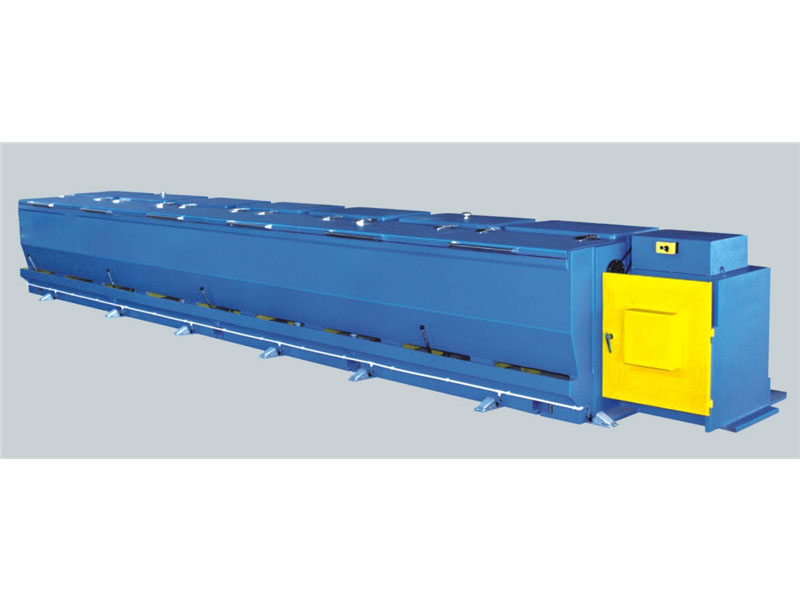

Koporo e tsoelang pele ea ho lahla le ho roala-mohala oa koporo oa CCR

-Mochini oa mabili a mahlano o nang le bophara ba caster ea 2100mm kapa 1900mm le sebaka sa sefapano sa 2300 sqmm.

-2-Roll rolling process bakeng sa roll rolling e thata le 3-Roll rolling process ea ho qetela

-Rolling emulsion system, gear lubricating system, pholileng le lisebelisoa tse ling tse etselitsoeng ho sebetsa le leloala le rolling.

-PLC e laola ts'ebetso ho tloha ho caster ho ea ho coiler ea ho qetela

- Sebopeho sa coiling ka mofuta oa orbital se hlophisitsoeng; compact coil ea ho qetela e fumanoeng ke sesebelisoa sa hydraulic press -

Mochini oa ho Arola Molamu o nang le Li-Drives tsa Motho ka Mong

• moralo oa tandem o otlolohileng

• motho ka mong servo drive le tsamaiso ea ho laola

• Siemens reducer

• tsamaiso e pholileng ea metsi / emulsion ka ho feletseng bakeng sa bophelo bo bolelele ba tšebeletso -

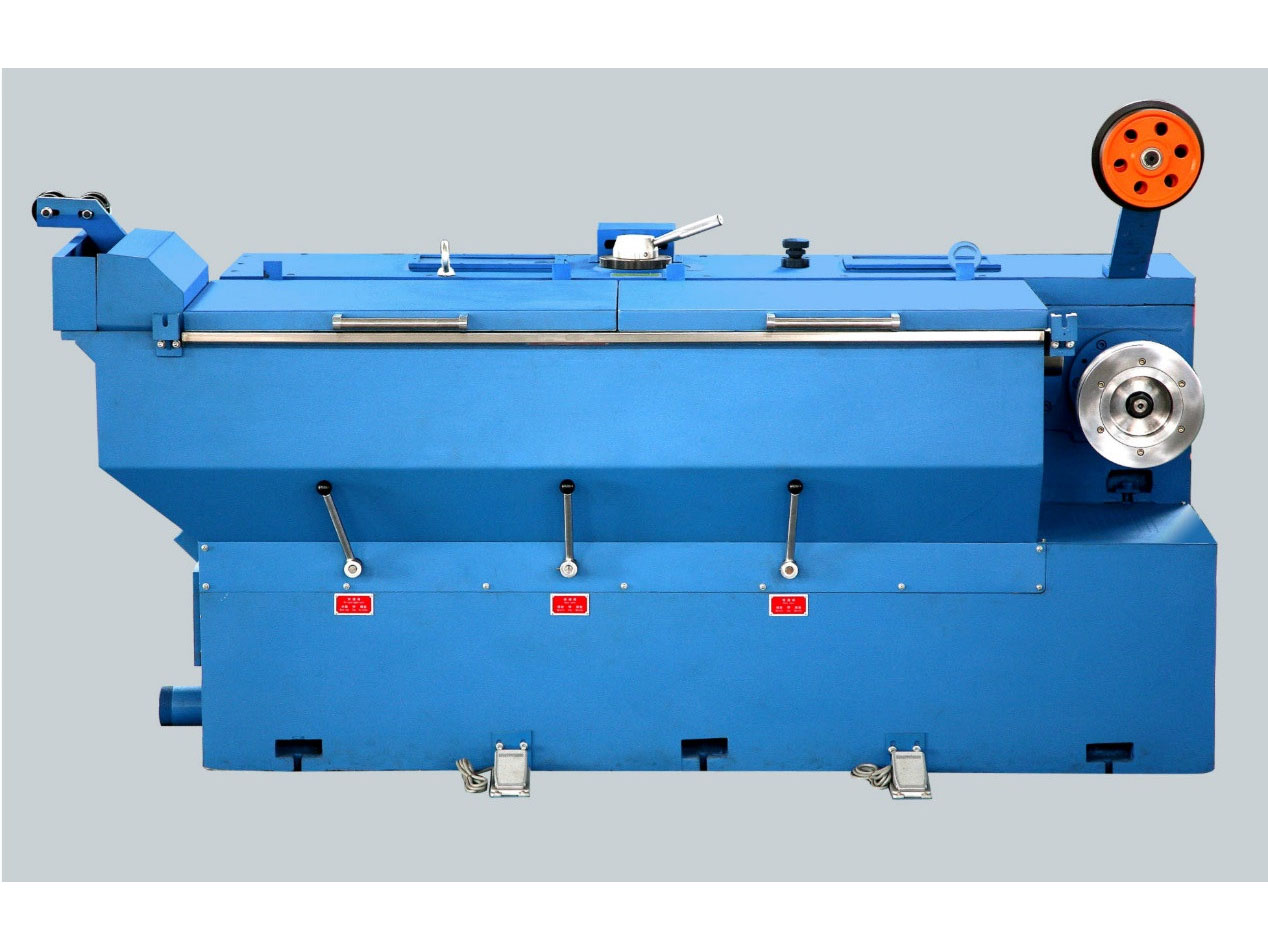

Mochini oa Copper/ Aluminium/ Alloy Rod Sekhahla

• moralo oa tandem o otlolohileng

• qobella ho pholisa/ ho tlotsa ho tsamaisa oli ea phetiso

• lisebelisoa tse nepahetseng tsa helical tse entsoeng ke lisebelisoa tsa 20CrMoTi.

• tsamaiso e pholileng ea metsi / emulsion ka ho feletseng bakeng sa bophelo bo bolelele ba tšebeletso

• Moralo oa tiiso ea mochini (e entsoe ka pane ea ho lahla metsi, selikalikoe sa ho lahla oli le tšoelesa ea labyrinth) ho sireletsa karohano ea emulsion ea ho taka le oli ea gear. -

Mohala o Matla o Phahameng oa Multi Wire Drawing Line

• moralo o kopaneng le mehato e fokolitsoeng

• qobella ho pholisa/ ho tlotsa ho tsamaisa oli ea phetiso

• helical precision gear le shaft e entsoeng ka thepa ea 8Cr2Ni4WA.

• Moralo oa tiiso ea mochini (e entsoe ka pane ea ho lahla metsi, selikalikoe sa ho lahla oli le tšoelesa ea labyrinth) ho sireletsa karohano ea emulsion ea ho taka le oli ea gear. -

Mochini o Ratang oa Hare o Matla o Phahameng

• moralo oa mofuta oa cone pulley

• qobella ho pholisa/ ho tlotsa ho tsamaisa oli ea phetiso

• lisebelisoa tse nepahetseng tsa helical tse entsoeng ke lisebelisoa tsa 20CrMoTi.

• tsamaiso e pholileng ea metsi / emulsion ka ho feletseng bakeng sa bophelo bo bolelele ba tšebeletso

• moralo oa tiiso oa mochini ho sireletsa karohano ea emulsion ea ho taka le oli ea gear. -

Mochini o Ratang Lithapo tse Hloekileng ka Bokhabane bo Phahameng

Mochini oa ho Etsa Lithapo tse Ntle • ho fetisoa ka mabanta a sephara a boleng bo holimo, lerata le tlase. • habedi converter drive, kamehla tsitsipano taolong, ho boloka matla • tšela ka ball scre Mofuta oa BD22/B16 B22 B24 Max inlet Ø [mm] 1.6 1.2 1.2 Outlet Ø range [mm] 0.15-0.6 0.1-0.32 0.08-0.32 No. 1 1 1 Nomoro ea liqapi 22/16 22 24 Max. lebelo [m/sec] 40 40 40 Ho atolosoa ha terata ka moralo o mong le o mong 15%-18% 15%-18% 8%-13% Mochini o Ratang oa Mohala o Botle o nang le Spooler e Phahameng ea Boleng • moralo o kopaneng bakeng sa ho boloka sebaka •... -

Horizontal DC Resistance Annealer

• ho rapameng DC resistance annealer e loketse metjhini e senyang melamu le metjhini e hohelang e mahareng

• taolo ya dijithale annealing voltage bakeng sa terata ka boleng bo tsitsitseng

• Sistimi ea annealing ea libaka tsa 2-3

• naetrojene kapa sistimi ea tšireletso ea mouoane bakeng sa ho thibela oxidization

• moralo oa mochini oa ergonomic le o bonolo oa mosebelisi bakeng sa tlhokomelo e bonolo -

E otlolohileng DC Resistance Annealer

• vertical DC resistance annealer bakeng sa mechine ea ho taka e bohareng

• taolo ya dijithale annealing voltage bakeng sa terata ka boleng bo tsitsitseng

• 3-zone annealing system

• naetrojene kapa sistimi ea tšireletso ea mouoane bakeng sa ho thibela oxidization

• moralo oa ergonomic le o bonolo oa mosebelisi bakeng sa tlhokomelo e bonolo -

Coiler ea boleng bo holimo / Barrel Coiler

• ho bonolo ho sebelisoa mochine oa ho senya molamu le mohala oa mochine oa ho taka oa bohareng

• e loketseng libarele le li-cardboard barrel

• Moralo oa eccentric rotating unit bakeng sa terata e tshekaletseng e nang le rosette e behang, le ho sebetsa ntle le mathata. -

Automatic Double Spooler e nang le Fully Automatic Spool Changing System

• moralo oa spooler habeli le sistimi ea ho fetola spool ka botlalo bakeng sa ts'ebetso e tsoelang pele

• tsamaiso ea koloi ea AC ea mekhahlelo e meraro le motlakase oa motho ka mong bakeng sa ho tšela mohala

• spooler ea mofuta oa pintle e feto-fetohang, mefuta e mengata ea boholo ba spool e ka sebelisoa