Mechini e Thusang ka Mechini ea ho Rala Lithapo tsa tšepe

Ho lefa

Tefo ea Hydraulic vertical: Lithupa tse peli tse otlolohileng tsa haeteroliki tse bonolo ho kengoa ka terata le tse khonang ho thiba terata ka linako tsohle.

Tefo e tshekaletseng: Meputso e bonolo ka dikutu tse pedi tse sebetsang tse loketseng mehala ya tshepe e phahameng le e tlase. E ne e ka laela likhoele tse peli tsa molamu tse hlokomelang hore molamu oa terata o ntse o putlama.

Tefo ea ho feta: Tefo ea mofuta o sa sebetseng bakeng sa likhoele tsa terata 'me e na le lirolara tse tataisang ho qoba ho senyeha ha terata.

Tefo ea Spool: Tefiso e tsamaisoang ke enjene ka ho lokisa spool ea moea bakeng sa ho thella ha terata e tsitsitseng.

Lisebelisoa tsa terata pele ho kalafo

Molamu oa terata o tlameha ho hloekisoa pele o hula. Bakeng sa molamu oa terata ea khabone e tlase, re na le mochini o theolelang le oa borashe o tla lekana ho hloekisa bokaholimo. Bakeng sa molamu o phahameng oa terata, re na le mohala o se nang mosi oa ho khetha ho hloekisa molamu hantle. Lisebelisoa tsohle tsa pele li ka kenngoa ka har'a mochini oa ho taka kapa li ka sebelisoa ka thoko.

Likhetho tse fumanehang

Mochini oa ho theola lirolara le oa borashe:

Sehlahisoa sa lebanta la lehlabathe

Mohala oa pickling o se nang mosi

Nka-ups

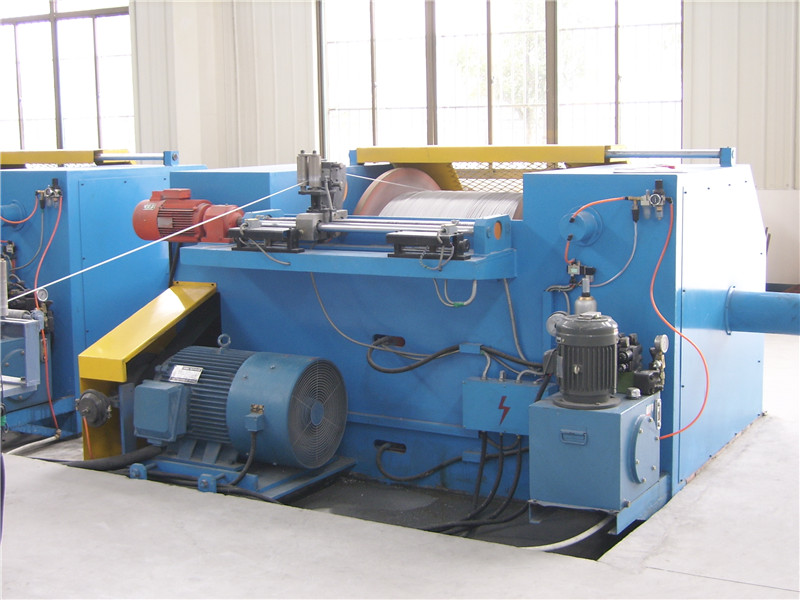

Coiler: Re ka fana ka letoto le felletseng la li-block block coiler bakeng sa boholo bo fapaneng ba terata. Li-coiler tsa rona li entsoe e le sebopeho se tiileng le lebelo le holimo la ho sebetsa. Re boetse re na le li-turntable tsa li-coil tsa boima ba 'mele ho fihlela litlhoko tsa bareki. Melemo ea ho sebelisa sekoahelo se shoeleng molemong oa ho taka terata ke ho felisa boloko bo le bong mochining oa ho taka oa terata. Bakeng sa ho kopanya terata ea tšepe e phahameng ea carbon, coiler e fanoa ka die le capstan 'me e na le sistimi ea eona ea ho pholisa.

Spooler: Li-spooler li sebetsa hammoho le mechini ea ho taka ka terata ea tšepe 'me li sebelisetsoa ho nka lithapo tse hutsoeng ho li kenya ka har'a li-spools tse thata. Re fana ka letoto le felletseng la li-spooler bakeng sa boholo bo fapaneng ba terata bo huloang. Spooler e tsamaisoa ke enjene e arohaneng mme lebelo la ho sebetsa le ka hokahanngoa le mochini oa ho taka

Mechini e meng

Butt welder:

● Matla a phahameng a ho koala lithapo

● Khomphuta e nyane e laoloang bakeng sa ho tjheseletsa le ho tjheseletsa ka boiketsetso

● Tokiso e bonolo ea sebaka sa mehlahare

● Ka yuniti ea ho sila le mesebetsi ea ho itšeha

● Lisebelisuoa tsa ho hokela tsa mefuta ka bobeli lia fumaneha

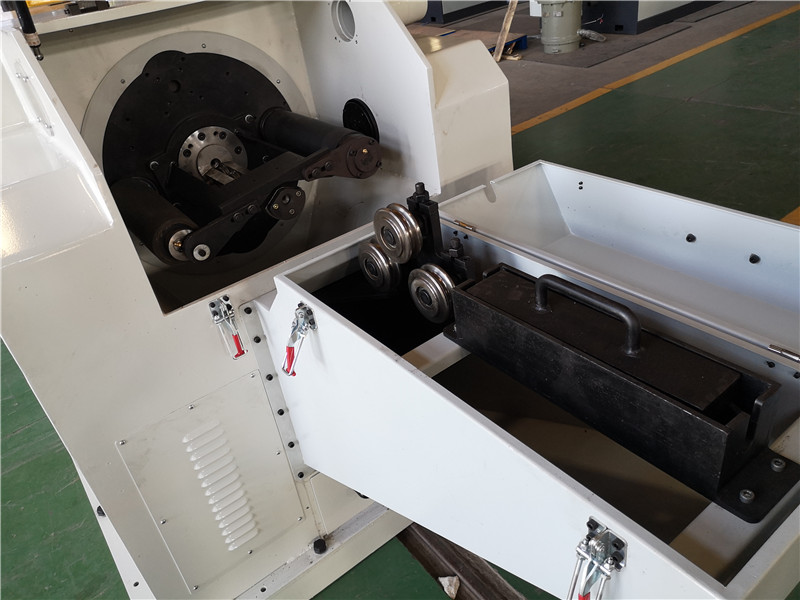

Sesupa sa mohala:

● Sesebediswa sa ho hulela ho fepela terata pele ho mothapo wa ho taka

● Lirolara tse thata tse sebetsang nako e telele

● 'Mele oa mochini o tsamaeang hore o sebetse habonolo

● Enjene e matla e khannoang bakeng sa lirolara