Mochini o Omileng oa Mohala oa Ts'epe

Likaroloana

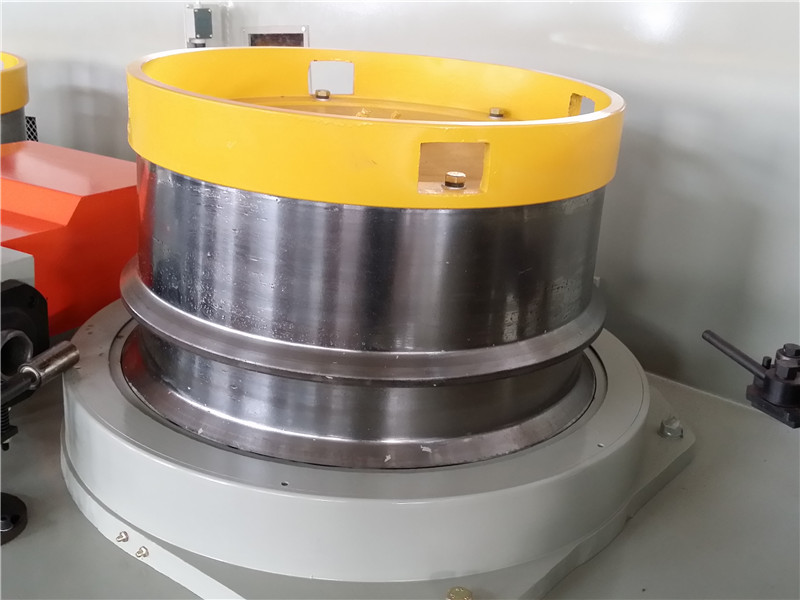

● Capstan e entsoeng kapa e entsoeng ka thata ea HRC 58-62.

● Phetiso e sebetsang hantle ka lebokose la gear kapa lebanta.

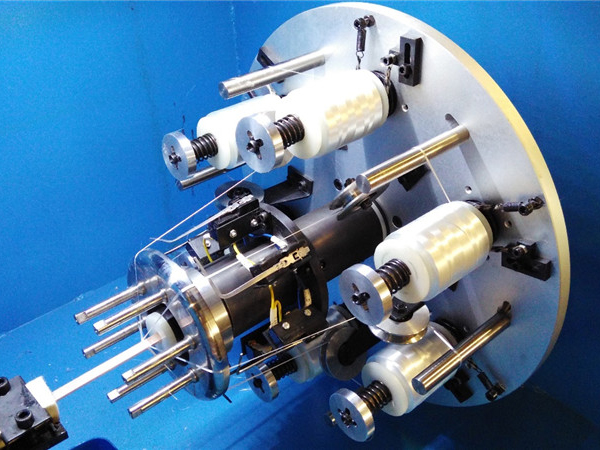

● Movable die box bakeng sa phetoho e bonolo le ho fetoha habonolo ha lefu.

● Sistimi e phahameng ea ho futhumatsa ea capstan le die box

● Tekanyetso e phahameng ea tšireletso le tsamaiso e ntle ea taolo ea HMI

Likhetho tse fumanehang

● Lebokose le bilikang le nang le sesepa kapa k'hasete e bilikang

● Capstan e entsoeng ka maiketsetso le tungsten carbide e koahetsoeng ka capstan

● Ho bokella liboloko tsa pele tsa ho taka

● Thibela stripper bakeng sa ho khoaela

● Lisebelisoa tsa motlakase tsa machaba tsa boemo ba pele

Lintlha tse ka sehloohong tsa tekheniki

| Ntho | LZn/350 | LZn/450 | LZn/560 | LZn/700 | LZn/900 | LZn/1200 |

| Ho taka Capstan | 350 | 450 | 560 | 700 | 900 | 1200 |

| Max. Inlet Wire Dia.(mm) | 4.3 | 5.0 | 7.5 | 13 | 15 | 20 |

| Max. Inlet Wire Dia.(mm) | 3.5 | 4.0 | 6.0 | 9 | 21 | 26 |

| Min. Outlet Wire Dia.(mm) | 0.3 | 0.5 | 0.8 | 1.5 | 2.4 | 2.8 |

| Max. Lebelo la ho sebetsa(m/s) | 30 | 26 | 20 | 16 | 10 | 12 |

| Matla a Motlakase(KW) | 11-18.5 | 11-22 | 22-45 | 37-75 | 75-110 | 90-132 |

| Taolo ea Lebelo | Taolo ea lebelo la maqhubu a feto-fetohang a AC | |||||

| Boemo ba Lerata | Ka tlase ho 80 dB | |||||