Mechini e Tsoelang Pele ea Extrusion

Melemo

1, deformation ea polasetiki ea molamu oa ho fepa tlas'a matla a khohlano le mocheso o phahameng o felisang mefokolo ea ka hare ho molamu ka boeona ka ho feletseng ho netefatsa hore lihlahisoa tsa ho qetela tse nang le ts'ebetso e ntle ea sehlahisoa le ho nepahala ho phahameng.

2, eseng preheating kapa annealing, lihlahisoa tsa boleng bo botle tse fumanoeng ka mokhoa oa extrusion ka tšebeliso e tlase ea matla.

3, ka ho fepa ka lere la boholo bo le bong, mochini o ka hlahisa mefuta e mengata ea lihlahisoa ka ho sebelisa li-dies tse fapaneng.

4, mohala oohle o sebetsa habonolo ebile o potlakile ntle le mosebetsi o boima kapa tšilafalo nakong ea extrusion.

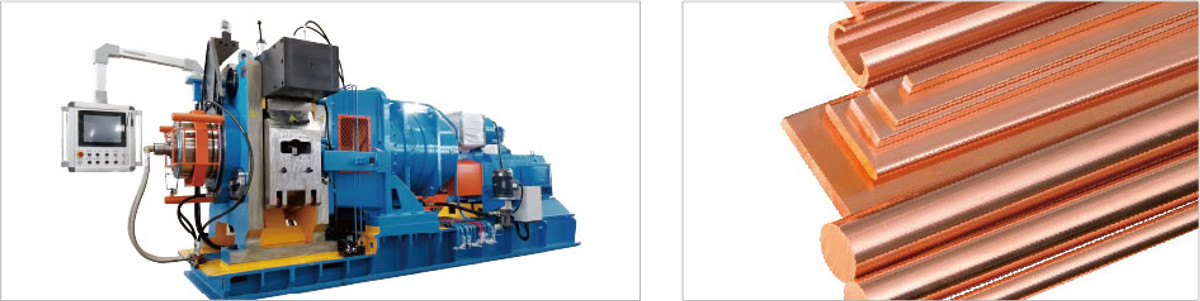

Ho fepa ka lere la koporo

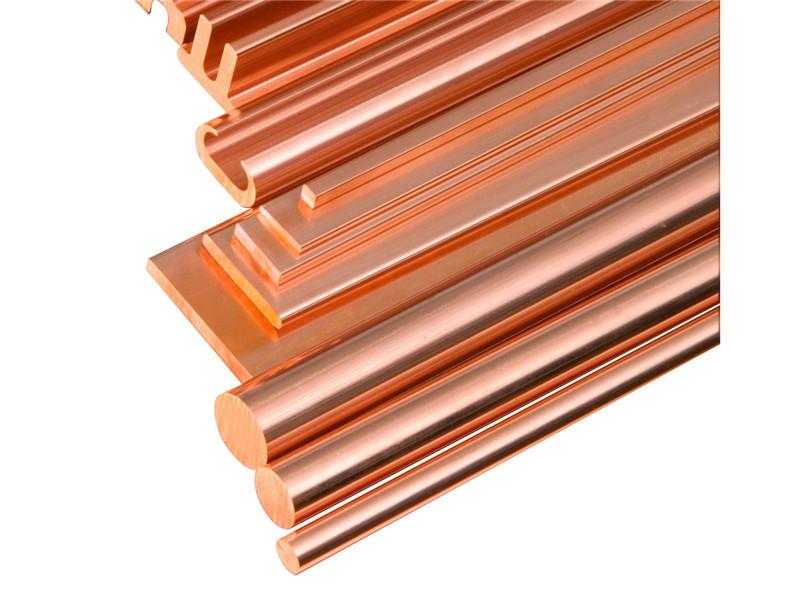

1.Ho etsa likhoele tse bataletseng tsa koporo, busbar e nyane ea koporo le terata e chitja

| Mohlala | TLJ300 | TLJ 300H |

| Main Motor Power(kw) | 90 | 110 |

| Molamu oa ho fepa dia. (mm) | 12.5 | 12.5 |

| Max. bophara ba sehlahisoa (mm) | 40 | 30 |

| Flat Wire Cross-Sectional | 5-200 | 5 -150 |

| Sephetho(kg/h) | 480 | 800 |

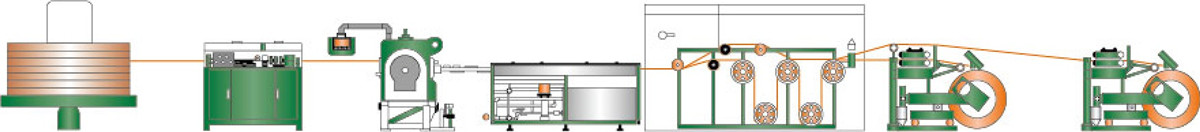

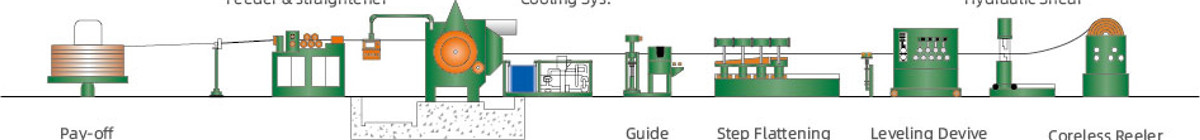

Tlhahiso ea Mola oa Tlhahiso

Pay-off Pretreatment Extrusion Machine Cooling Sys. Mochini oa ho Tants'a

2.Ho etsa busbar ea koporo, koporo e pota-potileng le profil ea koporo

| Mohlala | TLJ 350 | TLJ 350H | TLJ400 | TLJ 400H | TLJ 500 | TLJ 630 |

| matla a motlakase a maholo(kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| molamu oa ho fepa dia. (mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max. bophara ba sehlahisoa (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| molamu oa sehlahisoa dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| Sehlahisoa ka bophara ba karolo (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| tlhahiso(kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

Tlhahiso ea Mola oa Tlhahiso

Pay-off Feeder & straightener Extrusion Machine Cooling Sys. Length Counter Product Bench Take-up Machine

3. Ho etsa busbar ea koporo, khoele ea koporo

| Mohlala | TLJ 500U | TLJ 600U |

| matla a motlakase a maholo(kw) | 355 | 600 |

| molamu oa ho fepa dia. (mm) | 20 | 30 |

| max. bophara ba sehlahisoa (mm) | 250 | 420 |

| max. karo-karolelano ea bophara ho botenya | 76 | 35 |

| botenya ba sehlahisoa(mm) | 3-5 | 14-18 |

| tlhahiso(kg/h) | 1000 | 3500 |

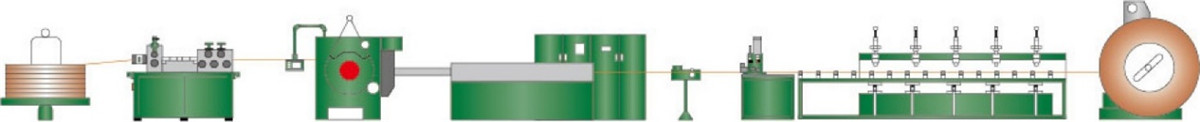

Tlhahiso ea Mola oa Tlhahiso

Ho fepa ka molamu oa koporo

Ho etsa kopo ea mokhanni oa likoloi, koporo e se nang letho, molamu oa koporo oa phosphor, mohala oa foreimi ea lead, terata ea seporo jj.

| TLJ 350 | TLJ400 | TLJ 500 | TLJ 630 | |

| thepa | 1459/62/63/65 brass cu/Ag (AgsO.08%) | phosphor koporo (Pso.5%) cu/Ag (AgsO.3%) | koporo ea magnesium (MgsO.5%) koporo ea tšepe (Feso.l% | koporo ea magnesium(MgsO.7%)/Cucrzr |

| molamu oa ho fepa dia. (mm) | 12/12.5 | 20 | 20 | 25 |

| max. bophara ba sehlahisoa (mm) | 30 | 150 (seaparo sa koporo sa silevera) | 100(sethapo sa foreimi e etellang pele :) | 320 |

| molamu oa sehlahisoa dia.(mm) | phosphor koporo: 10-40 | magnesium koporo: 20-40 | magnesium koporo: 20-40 | |

| tlhahiso(kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Tlhahiso ea Mola oa Tlhahiso

Pay-off Feeder & straightener Extrusion Machine Cooling Sys. Length Counter Take-up Machine

Ho fepa ka melamu ea aluminium

Ho etsa kopo ea terata e bataletseng, bara ea libese, le conductor ea profil, tube e chitja, MPE, le PFC Tubes

| Mohlala | LLJ300 | LLJ 300H | LLJ350 | LLJ400 |

| matla a motlakase a maholo(kw) | 110 | 110 | 160 | 250 |

| molamu oa ho fepa dia. (mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max. bophara ba sehlahisoa sa terata e bataletseng (mm) | 30 | 30 | 170 | |

| Sehlahisoa sa terata e sephara sebaka se arohaneng (mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| tube dia dia. (mm) | 5-20 | 5-20 | 7-50 | |

| bophara ba tube e bataletseng(mm) | - | ≤40 | ≤70 | |

| terata e bataletseng / tube Output(kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

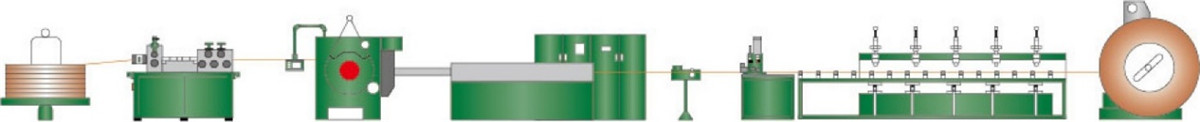

Tlhahiso ea Mola oa Tlhahiso

Mochine o otlollang o lefang Mochini oa ho hloekisa oa Ultrasonic oa Cooling Sys Dancer Take-up Machine

Setšoantšo sa 217282